FORD GODZILLA SWAP GUIDE

Christian2024-04-15T11:32:26-04:00Ford’s “Godzilla” V8 7.3L, 445ci pushrod motor is a major step away from Ford’s overhead-cam modular approach to engines. It delivers a massive 475 lb-ft of torque in stock condition – just what’s needed to pull monster loads in full-size Ford trucks.

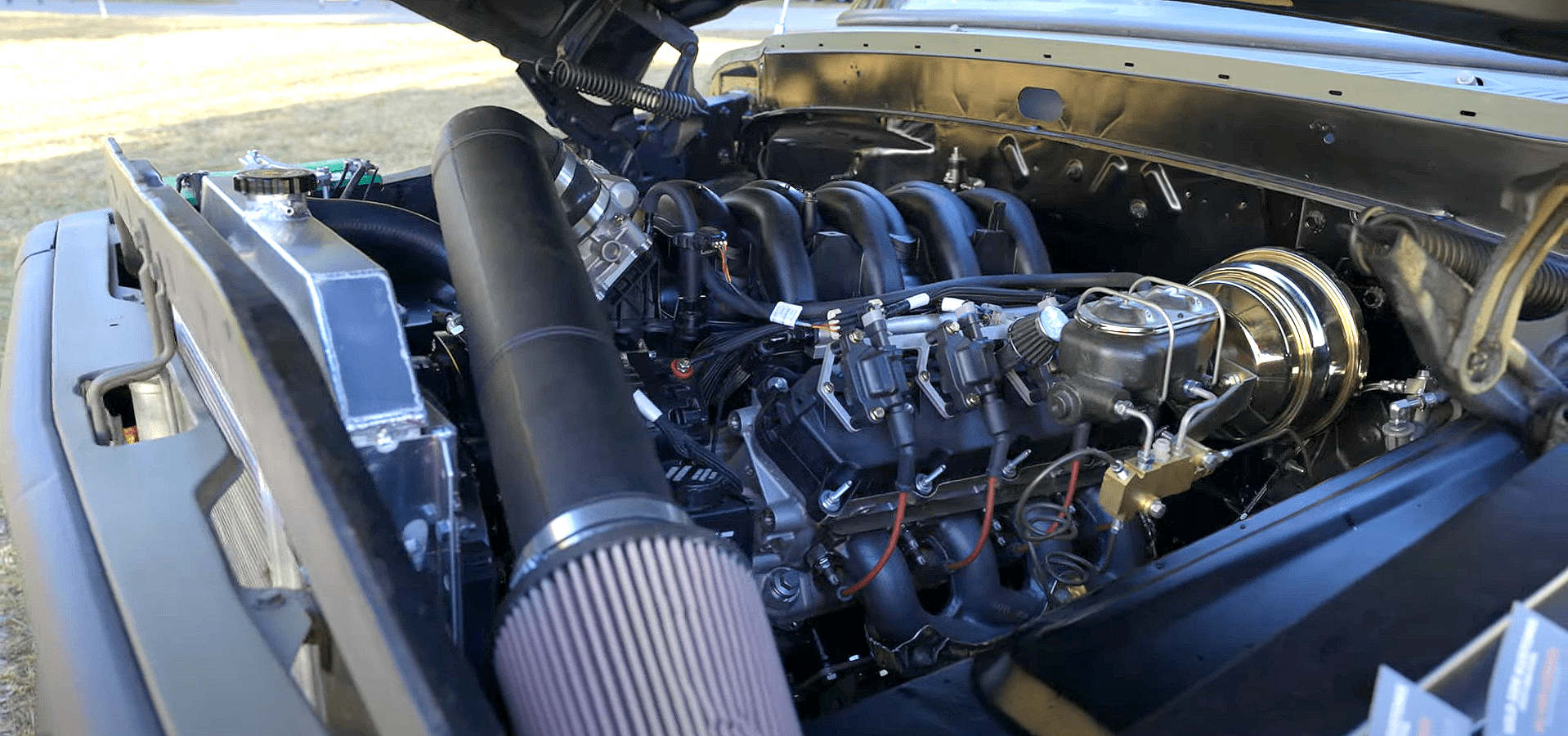

Of course, it took no time at all for Ford fans to consider this a prime engine swap candidate, especially for traditional muscle cars. The perennial issue with employing Ford’s Modular engines for swaps is width, especially for DOHC engines like the Coyote. But while the Godzilla engine is significantly narrower than a DOHC Mod motor, it offers its own challenges to those looking for a big-inch swap into the broad range of Mustangs, for example.

MIDSIZE MONSTER

The Ford 7.3L Godzilla is big – but not as massive as you might think. As you can see on this chart comparing bore spacing and deck height, the 7.3L Godzilla actually slots in the middle of Ford’s most popular pushrod V8 engines. Bore spacing determines overall engine length since that’s the distance between the cylinder centerlines. Wide bore spacing creates a longer engine, while a taller deck height creates a wider engine. Combining these two specs determines overall engine length and width.

| ENGINE | BORE SPACING (INCHES) | DECK HEIGHT (INCHES) |

|---|---|---|

| Ford 302W | 4.38 | 8.206 |

| Ford 351W Early | 4.38 | 9.480 |

| Ford 351W Late | 4.38 | 9.503 |

| FORD 7.3L GODZILLA | 4.53 | 9.650 |

| Ford 390 / 427 FE | 4.63 | 10.170 |

| Ford 429 / 460 | 4.90 | 10.320 |

The Godzilla’s 4.53-inch bore spacing and deck height of 9.65 inches positions this new pushrod V8 slightly taller and wider than a 351W but more compact than a Ford FE or 460. “The Godzilla engine is easier to fit headers and exhaust manifolds on than either the FE or 460 engines. “The exhaust manifold flange on the Godzilla’s head is recessed inside of the outer row of head bolts instead of on a vertical flange outside the head bolts as on the FE and 460 engines.”

OIL PUMP AND PAN

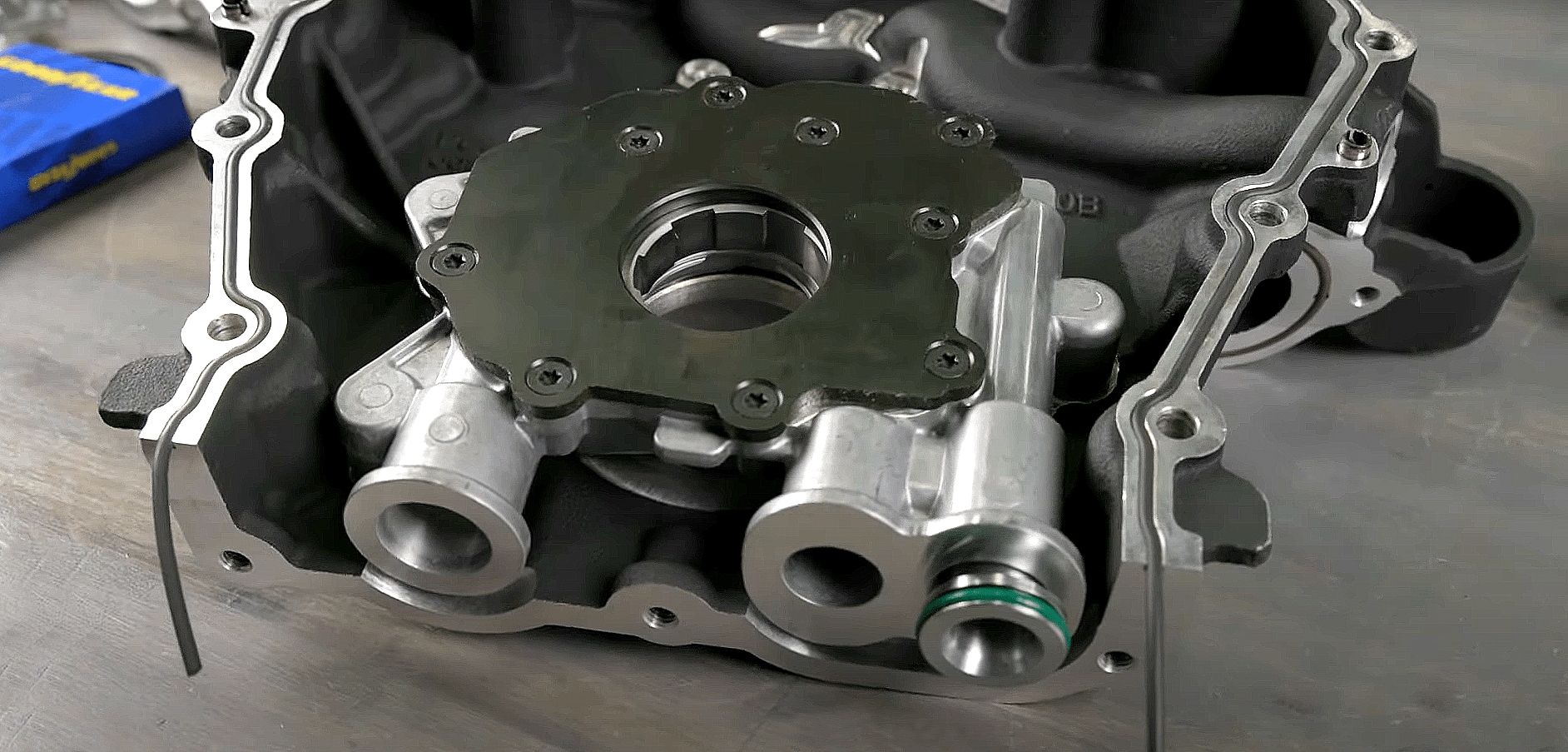

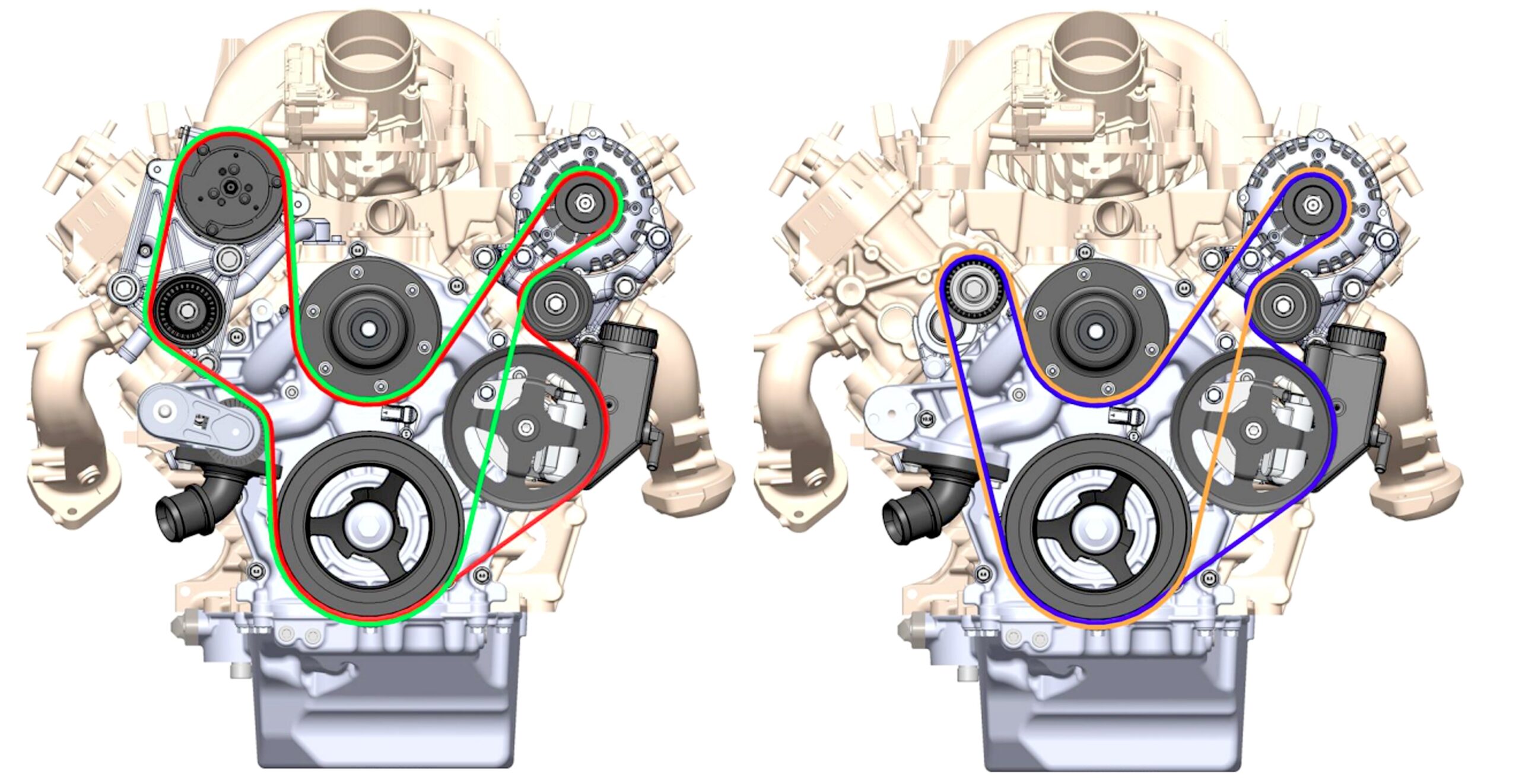

Taking a bottoms-up approach to the Godzilla, the factory oil pump placement and its deep oil pan are the first major impediments to swapping success. The Godzilla’s OE oil pump is actually located in the middle of the engine and is powered by a jackshaft driven off a secondary gear-and-chain assembly underneath the front timing chain cover. This system is designed to reduce the length of the suction pipe on the oil pump, but it unnecessarily adds to both engine length and oil pan depth.

relocating the oil pump on the crankshaft snout under the front cover, much like other modern engines such as the GM LS and the Chrysler Gen III Hemi. This move eliminates the cumbersome jackshaft oil pump drive, which produces a much shallower front oil pan that can snuggle the deep-skirt block much lower into any engine compartment.

The expanded kit’s new Melling gerotor oil pump attaches to the inside of the front timing cover with bolts that are torqued only after the cover is in place. Another advanced feature of the Holley cover is its dedicated O-ring seal around the entire perimeter where it meets the block. The Ford OE cover merely uses a thin strip of RTV. The internal connections for coolant and oil are sealed with O-rings in both covers.

Holley’s oil pump setup replaces the stock mid-mounted, jackshaft-driven pump with a Melling gerotor unit that mounts under the front cover like other contemporary V8s, such as the GM LS and Chrysler Gen III Hemi. Another advantage to the Holley cover is its O-ring seal instead of the OE version’s bead of RTV. Holley engineers also made pressure-lubing the engine easier: On the passenger side of the pan, there’s a fitting where a pressurized fill tank can push oil through the engine to pre-lube it before initial start. Similarly thoughtful is the Holley unit’s simple external access to the oil pressure relief spring.

Beyond sealing, the Holley pump arrangement also offers the additional benefit of external access to the oil pressure relief spring. So, if after installation there’s a need to adjust the relief valve spring pressure, the Holley cover makes this process quick and easy.

There are multiple options within the combinations of factory and aftermarket parts, so you should study the parts lists carefully. For example, there are some applications where the factory oil pan and pump system could be retained. In these situations, the basic Holley front timing cover kit could be applied since the cover is designed to accommodate the factory oil pump drive system.

ACCESSORY DRIVE

Another big hurdle to overcome when swapping Godzillas into Mustangs and other space-challenged vehicles is the engine’s stock accessory setup, which sits low and wide on the engine, adding considerable width to the overall package.

Rather than force buyers into a one-size-fits-all setup for the accessory drive, Holley offers its new Godzilla accessory drive system à la carte, much like the Burger King ads where you can “have it your way.” The accessory drive choices start with an alternator-only application that offers four choices for alternator output, ranging from 105 to 150 amps. If power steering is important, that’s available using a bolt-on integrated reservoir, pump, and pulley assembly. Then if you want to sweeten your 7.3L package with air conditioning, Holley has that covered as well with a compact A/C compressor. All these components are designed to be driven by the original Ford harmonic balancer/crank pulley, or an aftermarket unit can be used if desired. See details here

If you’re considering any of these accessory drive systems, it’s a smart move to read the online instructions that come with computer-generated images showing all the details necessary concerning the installation. Reading and studying these instructions will often answer questions and remove much of the doubt about which system is best for your application.

The new high-mount accessory drive package offers multiple options to run just an alternator, or alternator and power steering, or a complete system with alternator, power steering and a top-mounted A/C compressor.

This entire accessory drive adds a mere 6.75 inches of length from the factory Ford front cover mounting point, which is shallower than the depth of the Ford harmonic balancer. Plus, the system can perhaps be best described as high and tight. The A/C pump is moved to the upper passenger side of the engine, which makes frame rail interference much less likely. The same is true with the driver-side mounting of the alternator and power steering pump. Holley put plenty of thought into this regarding Ford engine compartments that are often space limited.

Take-out engines and Ford’s Godzilla crate engines using the stock timing cover require the use of an ECU-controlled alternator. To add further to the list of options for Godzilla fans, Holley offers an alternator bracket kit with or without a stand-alone alternator that doesn’t require ECU control, which makes engine swaps much easier when retaining the factory front cover.

See full line of Godzilla Accessory drive kits and components.

Holley’s drive setup moves the accessories from the factory low-and-wide location to more of a high-and-tight arrangement that reduces potential frame rail interference. The Holley unit is also shorter lengthwise: Measured from the block face mounting point for the timing chain cover, it’s only 6.75 inches to the water pump snout.

LOW-PROFILE INTAKE MANIFOLD

The most obvious change from the production unit is the Holley manifold’s repositioned throttle body. This is far more swap oriented, intelligently eliminating the steep 45-degree upward tilt of the factory Godzilla throttle body. The Holley manifold instead angles the throttle body downward 10.5 degrees, for 55.5 degrees of overall difference – a significant benefit when trying to fit the engine underhood in tight confines.

Beyond that, the manifold will also accommodate three different throttle body combinations: the factory 80mm 7.3L drive-by-wire (DBW) version, the cable-driven ’86-’95 Fox-body style, or the 92mm 2020-2023 GT500 version with an adapter. The manifold’s throttle body opening is 92mm but can be easily ported to 95mm if necessary.

While just these improvements are certainly worth the price of admission, the manifold itself has been massaged to lower its profile by 2 inches at the rear and 3.5 inches at the front compared to the OE design. The combination of all these factors makes this a smart approach.

But to add another incentive, the runner length has been modified to maintain midrange torque while enhancing top-end power. Holley’s early dyno testing reveals that the new manifold can maintain average torque within 3 lb-ft of the factory numbers between 2,500 and 6,200 RPM in an otherwise stock configuration. Average power is down only 1 hp when using the GT500 throttle body compared to the stock 7.3L configuration.

The shorter intake allows significantly more underhood clearance, with minimal penalty to performance. In dyno testing, torque was down only slightly compared to the stock manifold. Optimizing cam specs to suit this manifold will likely regain all of that power and then some.

Note that these numbers are averages using a stock camshaft. By shifting the manifold runner length to enhance peak horsepower, it’s common to lose torque at engine speeds below peak torque. It’s clear that when the 7.3L is enhanced with a more aggressive camshaft, the peak and average numbers will be far more impressive. Finally, the lower portion of the manifold is removable to allow porting or nitrous fittings.