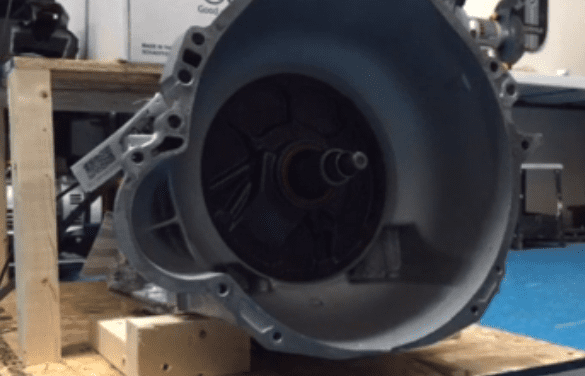

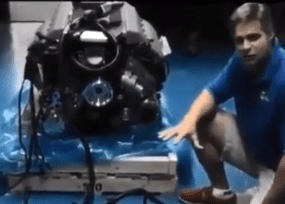

FORD GODZILLA SWAP GUIDE

Ford’s “Godzilla” V8 7.3L, 445ci pushrod motor is a major step away from Ford’s overhead-cam modular approach to engines. It delivers a massive 475 lb-ft of torque in stock condition – just what’s needed to pull monster loads in full-size Ford trucks. Of course, it took no time at all for...