Early Coyote Bronco Swap

CHRISTIAN NELSON2024-03-03T14:23:40-05:00Dropping a Coyote Engine into a Vintage Bronco

What do you do when you have a vintage Bronco and want stronger V-8 power? You probably look to Mustang engines. But what if you already have a hot rod pony powerplant and want more?

Perhaps a Coyote crate engine. This “Aluminator” engine is a 5.0L Four-Valve unit with an 11:1 compression ratio and comes complete with a manual transmission engine injector harness. Lamb Fab pulled the existing engine and started working to fit the wider, modular Ford V-8 under the hood. The work required modifications to the fender wells, front cowl, steering shaft, and front driveshaft along with will all the other usual changes that have to be made when a different engine is swapped in. Front Runner Pulley system

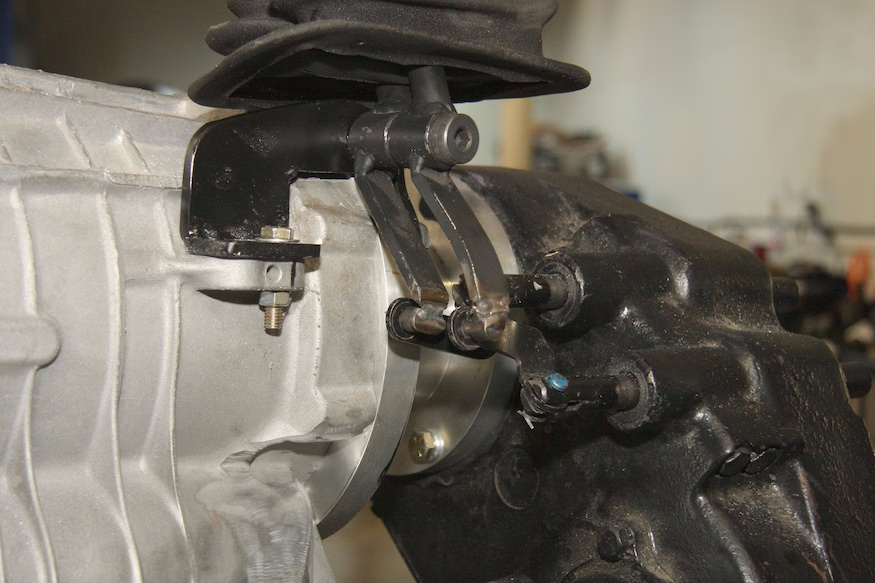

For this swap, the Coyote engine was mated to a six-speed auto. This, in turn, was adapted to the existing Dana 20 transfer case that has a twin-stick shifter setup.

Follow along as we detail some of the tasks needed to complete this swap. The results are impressive, to say the least. With 435-plus horsepower on tap, there are plenty of ponies to make this Ford Bronco swap move rapidly. With the backing of the six-speed, the engine is always in powerband and drivability is awesome, especially when compared to the older three-speed C4 auto it had previously. It is supersmooth now.

The complete powertrain is temporarily assembled for test fitting. It is a clean setup adapting modern to vintage for this classic Ford. The six-speed auto transmission In the final configuration, driveshaft lengths were unchanged. However, some mods were made to the front driveshaft to clear the larger transmission. No CV joint was used, but high-angle U-joints were needed.

An adapter was sourced to mate the modern auto transmission to the Dana 20 that was already in the Ford Bronco swap. Multiple bolt holes on the adapter allow for numerous clocking configurations to place the t-case at almost any angle relative to the transmission.

To best mate the engine to the Coyote Bronco swap frame rails and make moving the engine in and out easier, an engine cradle was fabbed under the oil pan that bolts to the full-metal engine mount plates using urethane bushings. The cradle then sits in a set of pocket brackets on the frame rails. Determining the final engine placement took some time to ensure that the hood, radiator, and firewall clearances were maintained.

Ford Racing headers were used but modified a bit to fit around the inner fenders and steering shaft. Cut off and reworked some of the tubes as needed.

The Coyote engine computer itself monitors water temperature and oil pressure. Autometer gauges used in the dash. The mechanical water temp sensor was plumbed into one of the heater ports on the new engine.

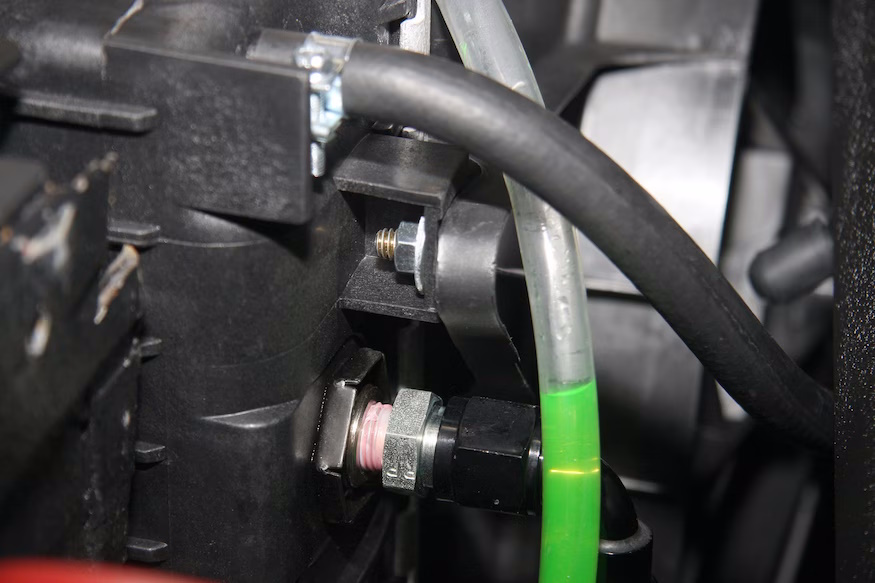

Since the Coyote engine was primarily designed for late-model Mustangs that use electric power steering, no steering pump is provided on the engine. Use of a Front Runner Setup includes the Power Steering Pump and AC Compressor

As work progressed, the engine was placed in and pulled out of the engine bay a number of times for fit checks. The Coyote engine is a good bit wider across the cylinder heads than the older 302 V-8 it replaces. The Coyote Bronco swap uses a 1980s Ford 2WD steering box and a Borgeson shaft. The position of the Ididit steering column had to be modified, as did the inner fender panel in order to push the steering shaft a bit more to the driver side to clear the wider engine. You can also see the beginning of a frame mount to capture the engine cradle

The shop fabricated this simple, high-clearance mount for the adapter at the end of the transmission. It mates with two pairs of tabs on the inner frame rails and attaches with two bolts.

The radiator is from a late-model Thunderbird; it is very slim and packaged well. The Coyote engines are quite thermally efficient, so very large volumes of coolant aren’t needed. A 60-plus-psi inline electric pump was installed along the frame rail to feed fuel to the new engine.

The radiator is a closed-style, having no top radiator cap. An inline radiator fill assembly was used, simply spliced into the upper radiator hose. Hoses are late-model Mustang pieces. All hoses were secured with heat-shrink hose clamps.

These modern motors usually require a cooling system steam line. In this case, it was run with a rubber hose to a connection at the top of the radiator. This radiator also had an integrated cooler for the transmission fluid with inlet and outlet connections.

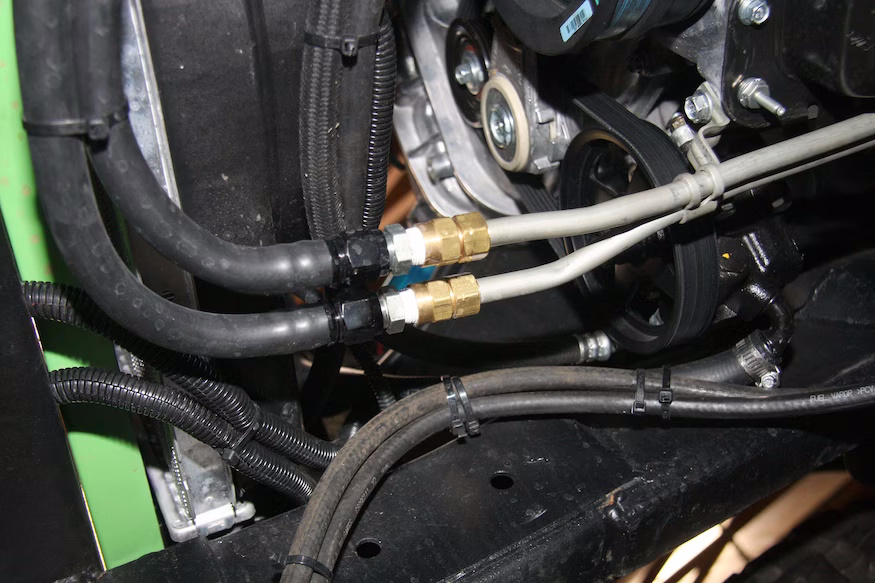

A set of factory Ford steel fluid lines was mated to the automatic transmission and routed forward. They were cut off just forward of the crank pulley, and compression fittings were used to adapt to rubber lines leading to the cooler integrated into the radiator. Also tucked up on the bottom side of the engine is an OEM Ford starter. Wiring was straightforward, and the existing Coyote Bronco swap connections were all used on the new starter.

A remote power steering reservoir from a late-model Mustang was mounted up near the cowl on the passenger side along with a small cooler for the steering system. Low- and high-pressure pump lines were custom fabricated and run from the pump on the passenger side to the steering box on the driver side.

auto shifter from the 2013 F-150 that’s designed to work with the six-speed transmission. Functions include manual tap-shift capability and tow/haul mode selection. The shop fabricated a metal console to mount and house the shifter, then had it covered in bed liner material to match the interior floor of the Coyote Bronco swap.

The transfer case shifter assembly was custom fabricated. The shifter mount is bolted to a tab point on the new transmission.

The Coyote engine control uses signals from a drive-by-wire throttle assembly so no mechanical throttle cable routing is necessary. Installed an accelerator pedal assembly from a 2013 F-150.

A Ford Racing engine harness was used along with the engine computer. It was programmed and sits on the passenger-side wheel well just ahead of the battery. These units are designed to survive heat and vibration under the hood, so mounting here is no problem. A Bussman fuse box on the inner fender provides overcurrent protection and cleans up the power supply wiring.

Along with using the slim radiator with the new engine, cut out much of the original cowl. then bridged the area with a new cross member that preserves the strength but is much more compact.

5.0 Coyote Swap packages

The air intake was put together from generic air intake fittings, and a large Spectre open element filter was isolated in a cold air box. The finished engine swap looks super clean sitting in the Coyote Bronco Swap. It fits, but there’s very little leftover airspace under the hood.

To help better assist with lifting the engine, we have our Coyote Lift Brackets available for purchase. Coyote 5.0 Lift Brackets are properly curved and shaped so when lifting up the 5.0 V8 Coyote engine its evenly spaced. Easy to Use. Can store very easily too. Otherwise lifting with Chain makes it very difficult to lift evenly!

Review our Coyote Crate Engines Here

Leave a Reply

You must be logged in to post a comment.